Aluminum Composite Material (ACM) panels come in various thicknesses, each suited for different applications. These panels are widely used in modern exterior facades and architectural designs, with common thicknesses being 3mm, 4mm, and 6mm. Their importance lies in their durability, flexibility, and aesthetic appeal, making them a top choice for contemporary construction. In this article, we will explore the different ACM panel thicknesses, their components, and how they impact performance.

What is the Thickness of an Aluminum Composite Panel?

ACM (Aluminum Composite Material) panels come in various thicknesses depending on their application. The overall thickness includes aluminum layers and the core material sandwiched between them. Standard thicknesses range from 3mm to 6mm, but custom sizes are also available for specialized projects.

How Thick is an ACM Panel Usually?

Typically, ACM panels have a standard thickness of 3mm, 4mm, or 6mm. The choice of thickness depends on the application:

- 3mm ACM Panels: Ideal for signage, interior wall cladding, and lightweight structures.

- 4mm ACM Panels: Commonly used in exterior cladding, offering a balance between durability and weight.

- 6mm ACM Panels: Preferred for large-scale architectural projects where additional strength and insulation are required.

Standard ACM Panel Thickness

Standard ACM panel thicknesses include:

- 3mm (0.12 inches)

- 4mm (0.16 inches)

- 6mm (0.24 inches)

These sizes are widely accepted across industries due to their optimal balance of flexibility, durability, and ease of installation.

Best Aluminum Composite Panel Manufacturer in Toronto

For Non combustible core we use high strength mineral that ideal for commercial and high rises projects.

Wallcent.

What Are ACM Panels Made Of?

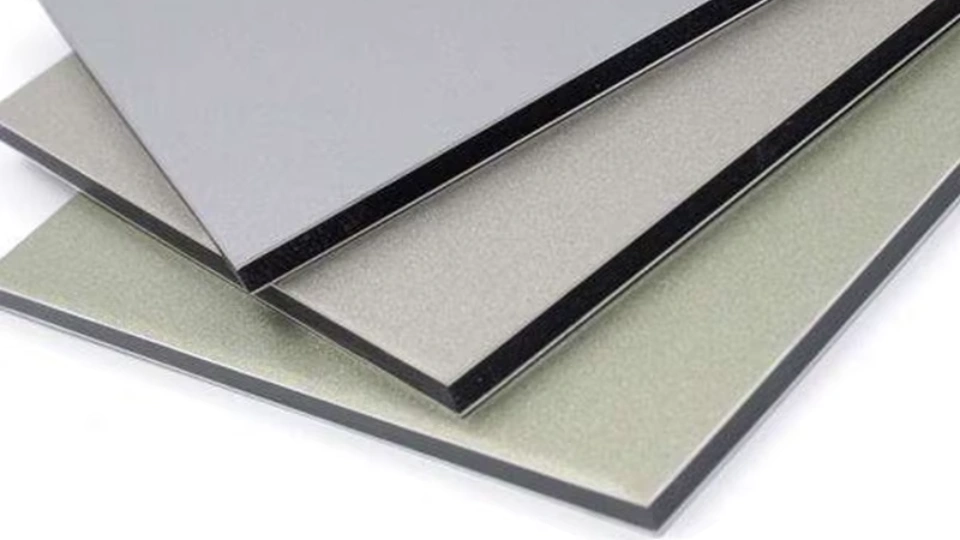

ACM panels consist of three primary layers:

- Aluminum Sheets: Two outer layers of aluminum, usually between 0.12mm to 0.50mm thick.

- Core Material: Sandwiched between the aluminum layers, the core can be:

- Polyethylene (PE): Lightweight and cost-effective.

- Fire-Retardant (FR) Core: Provides enhanced fire resistance, ideal for high-rise buildings.

- Aluminum Honeycomb Core: Increases strength while maintaining a lightweight profile.

- Coating Layer: The outer aluminum sheets are coated with PVDF (Polyvinylidene Fluoride) or PE coating for enhanced weather resistance.

How Does ACM Panel Thickness Affect Performance?

The thickness of an ACM panel impacts several key factors:

1. Strength and Durability

- Thicker panels offer greater impact resistance and durability.

- Ideal for high-traffic areas and long-term architectural solutions.

2. Flexibility and Ease of Installation

- Thinner panels (3mm) are easier to cut and shape.

- Thicker panels (6mm) require stronger support structures but offer better longevity.

3. Insulation and Soundproofing

- Thicker cores enhance thermal and acoustic insulation.

- Beneficial for reducing energy consumption in buildings.

4. Fire Resistance

- FR-core ACM panels (available in 4mm and 6mm thicknesses) provide enhanced fire safety.

- Essential for meeting building regulations in commercial and residential construction.

Choosing the Right ACM Panel Thickness for Your Project

1. Signage and Displays

- 3mm panels are commonly used due to their lightweight nature and ease of customization.

2. Exterior Cladding

- 4mm and 6mm panels offer superior durability and weather resistance.

- Fire-rated options are recommended for safety compliance.

3. High-Rise and Large-Scale Projects

- 6mm ACM panels provide enhanced structural integrity and longevity.

Comparison of ACM Panel Thickness Options

| Thickness | Best Use Cases | Advantages |

| 3mm | Signage, interiors | Lightweight, flexible, cost-effective |

| 4mm | Exterior cladding | Balanced durability and flexibility |

| 6mm | High-rise, large projects | Maximum strength and insulation |

Conclusion

Choosing the best ACM panel thickness is crucial for the success of your project. Whether you’re working on signage, exterior cladding, or a large-scale construction project, selecting the appropriate thickness ensures durability, safety, and aesthetic appeal. By understanding the different thickness options and their benefits, you can make an informed decision that enhances the performance and longevity of your installation.

FAQs

The most common ACM panel thickness is 4mm, as it balances durability, weight, and flexibility for exterior and interior applications.

Not necessarily. While thicker panels offer more strength, they are also heavier and may require additional structural support. The best choice depends on your specific project needs.

PE-core panels are cost-effective and lightweight, while FR-core panels offer enhanced fire resistance, making them ideal for safety-compliant buildings.

Yes, many manufacturers offer custom ACM panel thickness options to meet specific project requirements.

Consider factors like application, budget, durability, and fire safety requirements. For signage, 3mm is ideal, for cladding, 4mm or 6mm is recommended.